D15

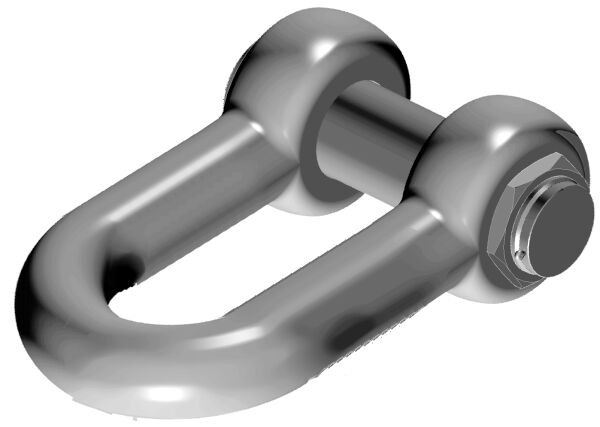

DEE SAFETY PIN SHACKLE

D14

END JOINING SHACKLE WITH ROUND PIN

D16

JOINING SHACKLE WITH PEAR SHAPE PIN

D17

ANCHOR SHACKLE WITH OVAL PIN

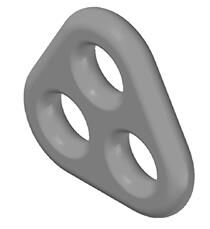

K17

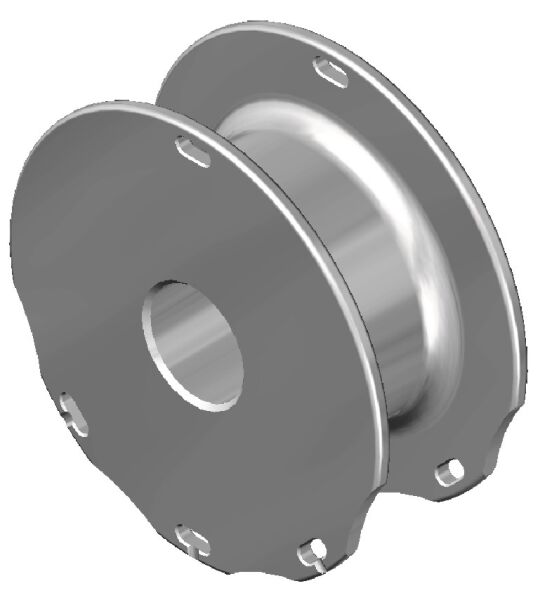

FORGED ROULETTE THIMBLE

SO5

PMS / LTM FORGED SOCKET

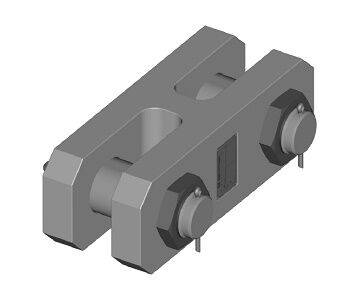

SC3

CR CONNECTOR

SC4

PEAR CONNECTING LINK

SC10

INSTALLATION LINK

SW6

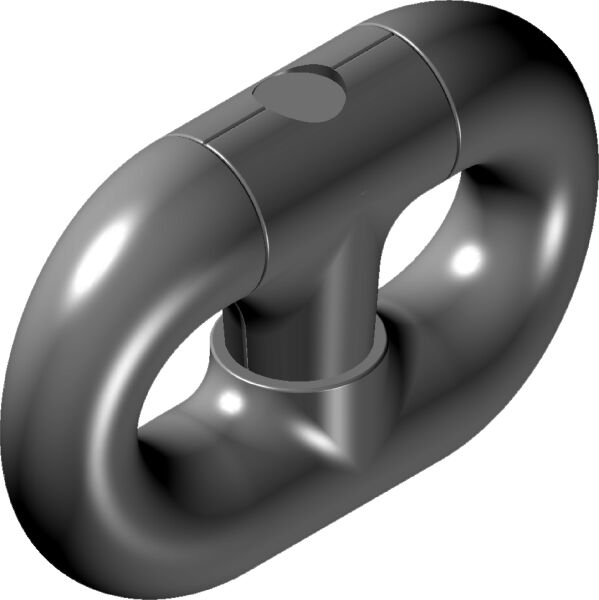

CR-X MOORING SWIVEL

Instructions mooring

D18

D-SHACKLE WITH ROULETTE THIMBLE

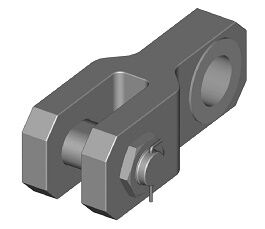

H15

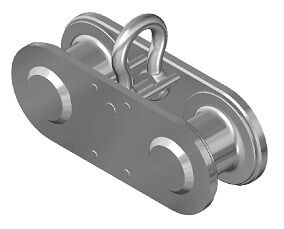

PLATE CONNECTOR / THIMBLE SHACKLE

SC8

FORGED H-LINK

SC9

FORGED Y-LINK

TR2