Instructions shackles

H9

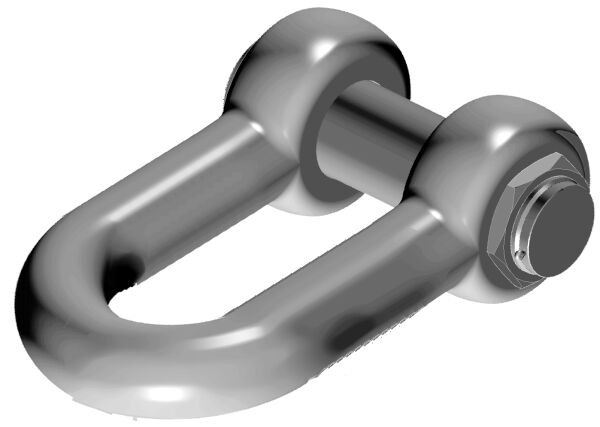

HIGH ALLOY SHACKLE

H10

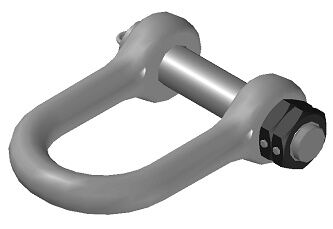

BOW SAFETY PIN SHACKLE

H10S

BOW SAFETY PIN SHACKLE [SUPER]

D15

DEE SAFETY PIN SHACKLE

H11

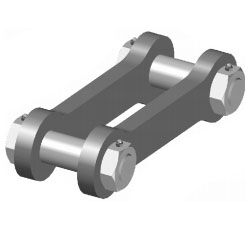

HEAVY DUTY DOUBLE NUT SHACKLE

H12

DOUBLE PIN / SNOTTER SHACKLE

H14

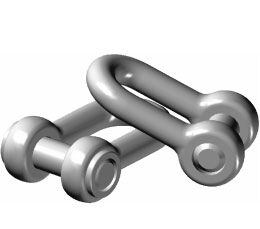

WIDE BODY SHACKLE

D10

CROWN PIN SHACKLE

D14

END JOINING SHACKLE WITH ROUND PIN

D16

JOINING SHACKLE WITH PEAR SHAPE PIN

D17

ANCHOR SHACKLE WITH OVAL PIN

SLIM

SLIMLINE PRODUCTS

ROV

ROV PRODUCTS

TUBE